Products

About Us

Ainuo Electronics Technical

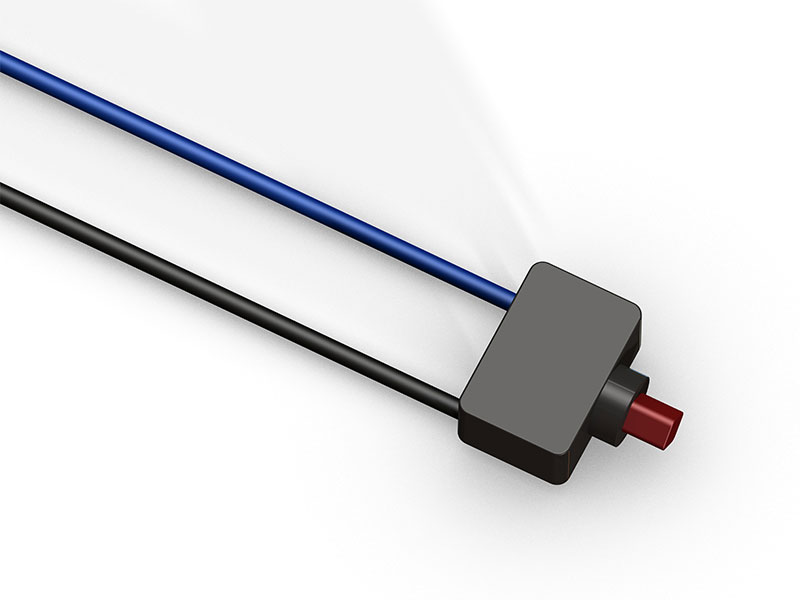

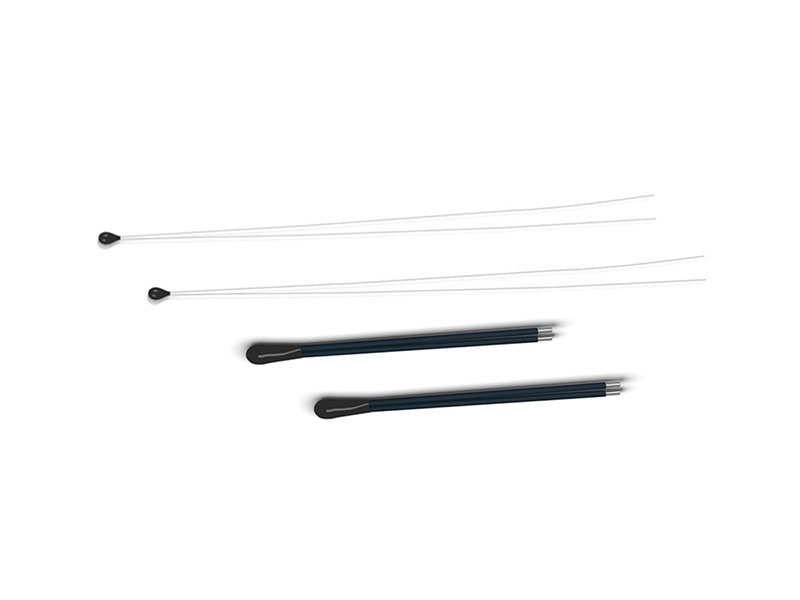

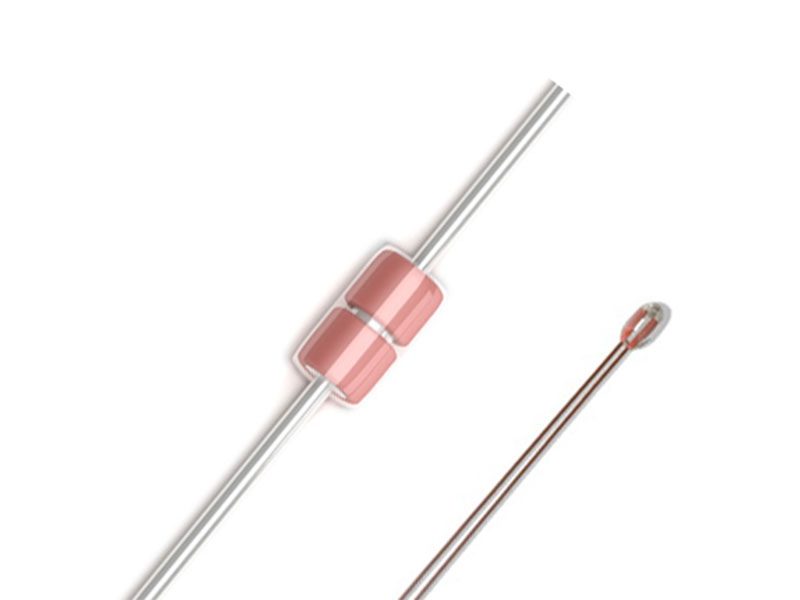

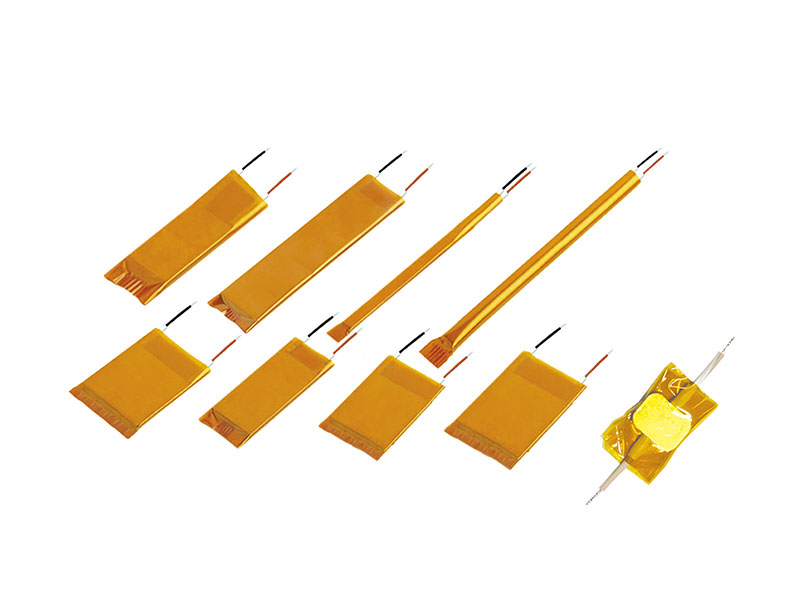

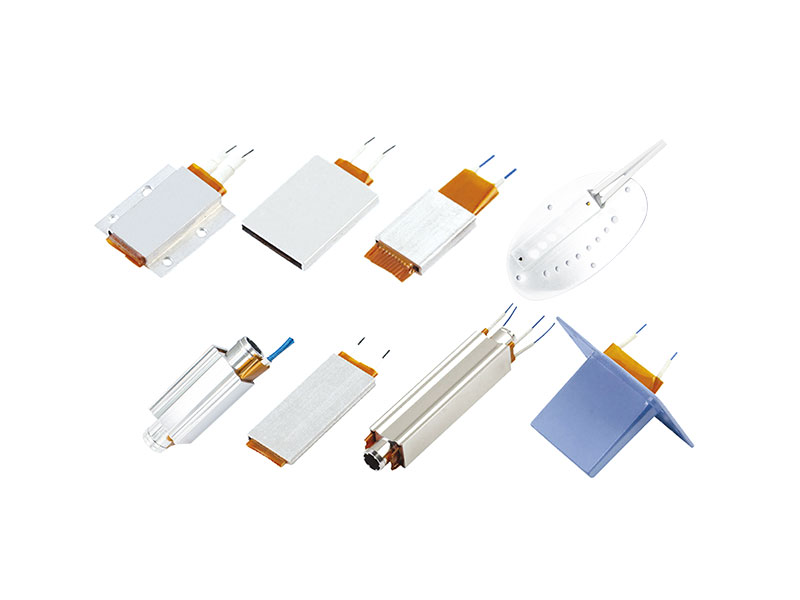

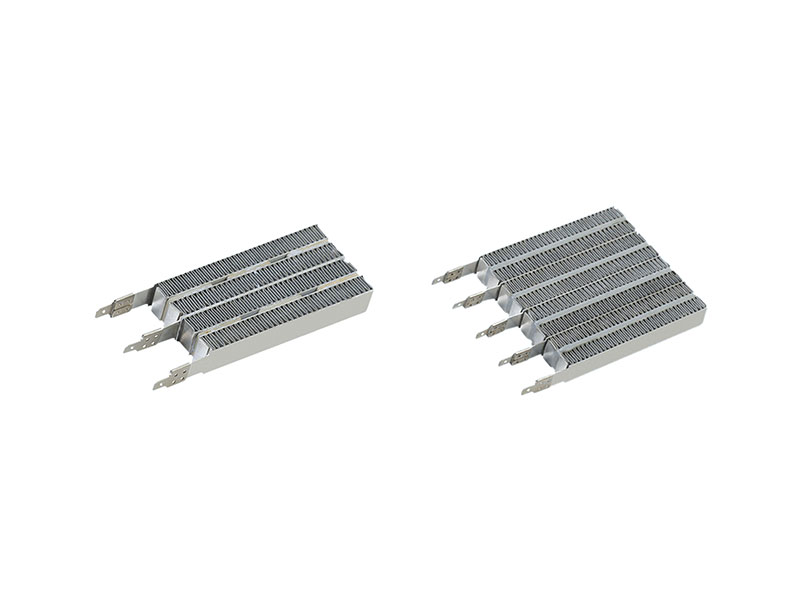

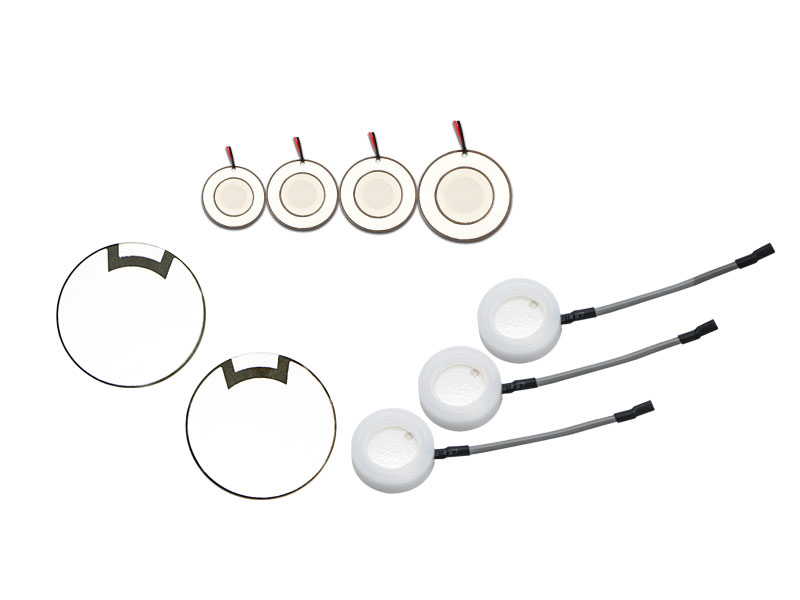

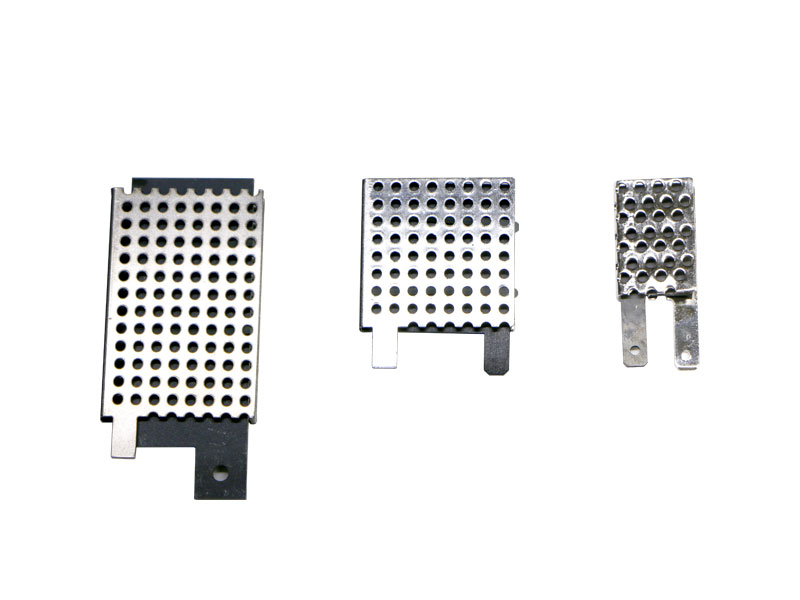

The company covers an area of more than 10,000 square meters, building area of 13,000 square meters, planning to build a new plant of 10,000 square meters, more than 500 employees, including 65 professional and technical personnel, since 2000, our company specializing in the development, production and sales of temperature control: KW series, 17AM series, 3MP series, 6AP series, MW, MC, ML series; Heating: PTC heater series, ceramic heater, mica heater series; Sensor: NTC temperature sensor series; Personal care categories: ultrasonic beauty, semiconductor refrigeration piece, sterilizer O ₃ generator and control products, such as changes in temperature in household appliances, transportation tools, electrical equipment, industrial equipment, sports health care equipment, personal care products, smart home, lighting and other fields, in aino company is committed to provide the best solution for related electronic products.

News

What are the specific applications of PT...

PTC heater is a special type of electric heating device, which differs from general resistance. The resistance value of PTC heater increases significantly with the increase of temperature. So what are the specific applications of this PTC heater? Below is a specific introduction to this issue!

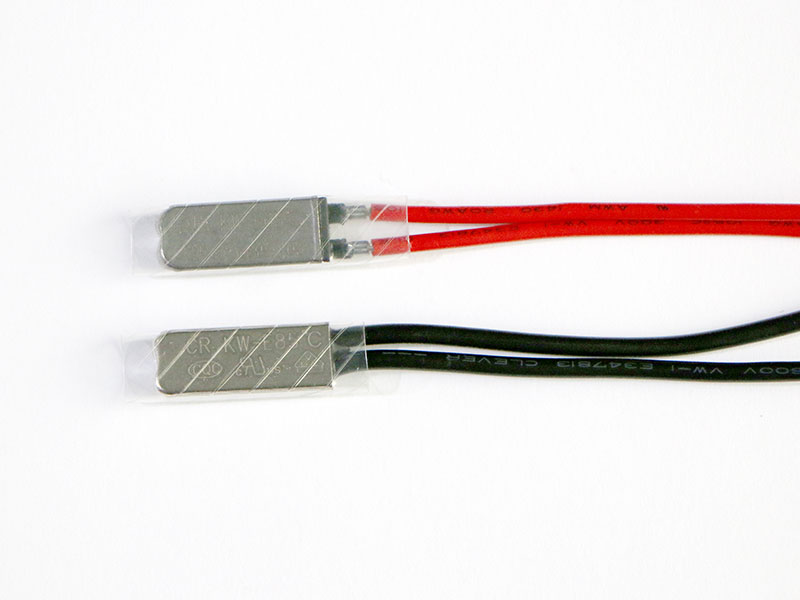

What are the functions of thermal protec...

A thermal protector is a sensor used to protect circuits or equipment from abnormal conditions such as overload, overheating, and short circuits. It is usually composed of one or more thermal resistors or thermistors, which can detect temperature changes to determine whether the circuit or equipment is in an overheated or overloaded state, and automatically cut off the power supply if necessary to protect the circuit or equipment from damage. So what are the functions of the thermal protectors here? Let the manufacturer of the thermal protector provide us with a detailed introduction!

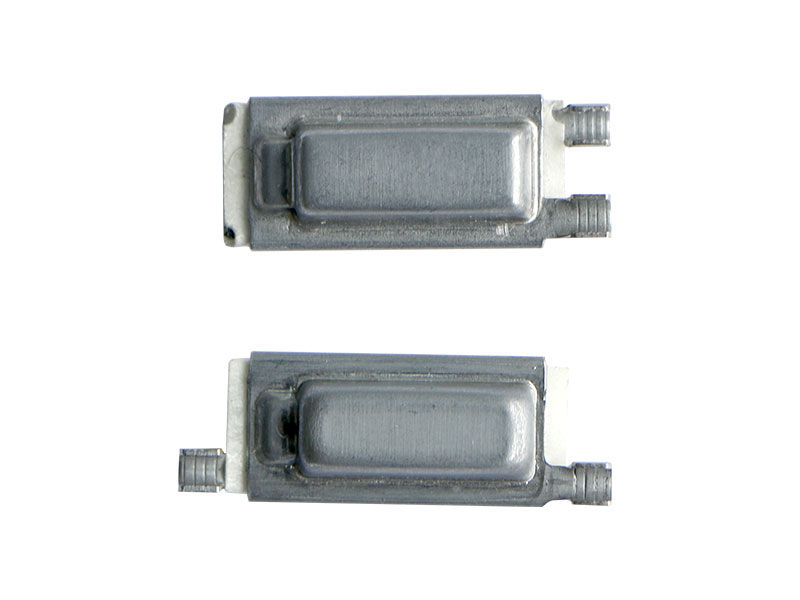

How the motor thermal overload switch wo...

When the motor thermal overload switch is in a closed working state, the movable contact maintains close contact with the static contact under the pre-pressure caused by the bending deformation of the leaf spring.