Categories

Product Overview

Provide a higher level of protection for flexible use of equipment with rotating parts

Ensure to pass the UL18-day integrated high-current locked-rotor test

Ensure strong protection under locked-rotor conditions

PTC self-sustained heating, power-off reset

Casing seal, flexible installation

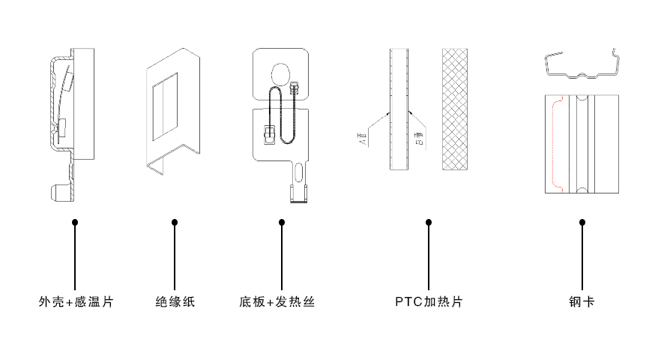

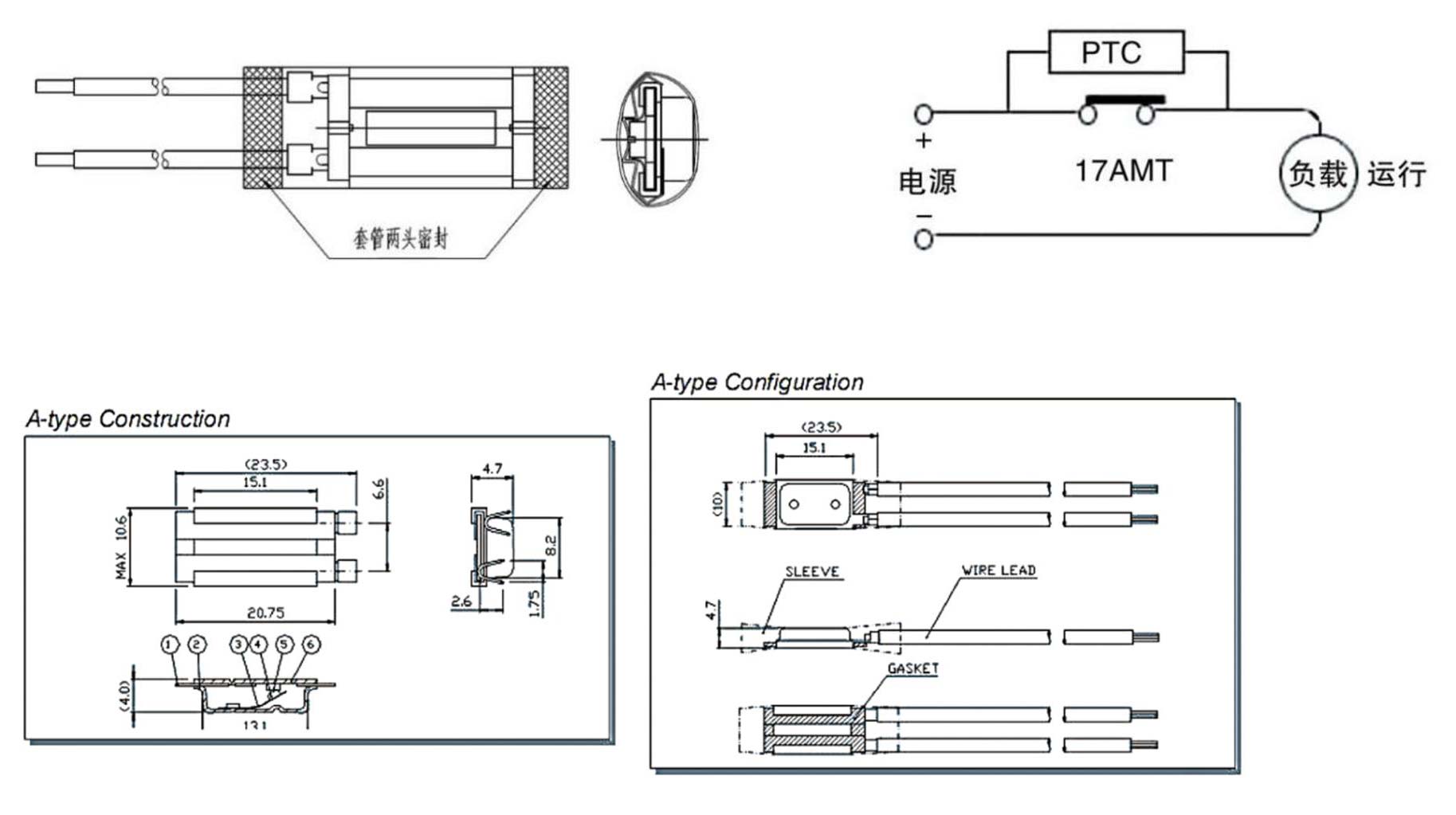

Design Principle

The 17AMT+PTC temperature/current protector is a derivative product of the 17AMT current and temperature double protection. PTC is set on the basis of 17AMT. The heating element and the protector contact form a parallel circuit. When the protector is separated, The PTC two poles get the voltage self-heating from the constant temperature, so that the temperature is conducted to the internal bimetal, causing the contacts to remain in a separated state, and the equipment is in a shutdown state for a long time, waiting for the equipment failure to be eliminated or the power supply to be cut off. After the power is cut off, the PTC stops heating, and the 17AMT can automatically reset after a certain period of heat dissipation and cooling, and the equipment will return to normal state. Therefore, 17AMT+PTC also has power-off protection and delay protection functions at the same time, achieving the function of manual reset, and its protection function is more reliable and complete. And in the manual reset product can be the first time that the user's electrical appliances are abnormal in use, the motor is blocked or the temperature rises to cause the protector to act, the protector can be locked once and will not be restored, and there will be no automatic reset for the second time. Damage to the human body caused by operating electrical appliances.

Contact capacity: | 125V AC 50A for TCO |

250V AC 30A for TCO | |

Temperature range: | 40℃ to 180℃ for TCO |

Disconnect temperature tolerance: | ±3℃, ±5℃, ±7℃, ±10℃, can be customized according to customer needs |

Automatic action: | Motor is 3C type |

The ballast is 2C type | |

TCO is 2B type | |

Working hours: | continuous work |

Pollution status: | conventional |

Sensing element range: | full control |

PTI value of insulating material: | 250 |

Protection level: | IP00 |

Electrical connection: | on the winding, plug-in type, clamping type, bracket type, glue type, etc. |

Scope Of Application

It is widely used in series motors, grinders, mixers, vacuum cleaners, washing machines, air compressors, garden tools, electric tools, water pumps, and all kinds of equipment with rotating parts.

UL&CUL: E258861 (UL2111 standard); E347255 (UL873&UL60730-1&UL60730-2-9 standard)

CQC: 10002045187 (GB14536.1-2008; GB14536.3-2008) motor thermal protector

10002045187 (GB14536.10-2008) multi-purpose temperature sensitive controller

10002048854 (GB14536.1-2008; GB14536.4-2008) ballast thermal protector

TUV: 50178359 (EN60730-1 standard, EN60730-2-9 standard)

VDE: 40030705 (EN60730-1 standard; EN60730-2-2 standard)

CB: CN33917 (IEC60730-2-2 standard)

Temperature Specification

Action temperature: 40~180℃±5℃, every 5℃, it is a temperature specification.

Reset temperature: In an environment of 25°C, the thermal protector will not automatically reset after tripping and without power failure. It will automatically reset after a power failure and a delay of 20-30 seconds.

External Structure

Number Naming Reference

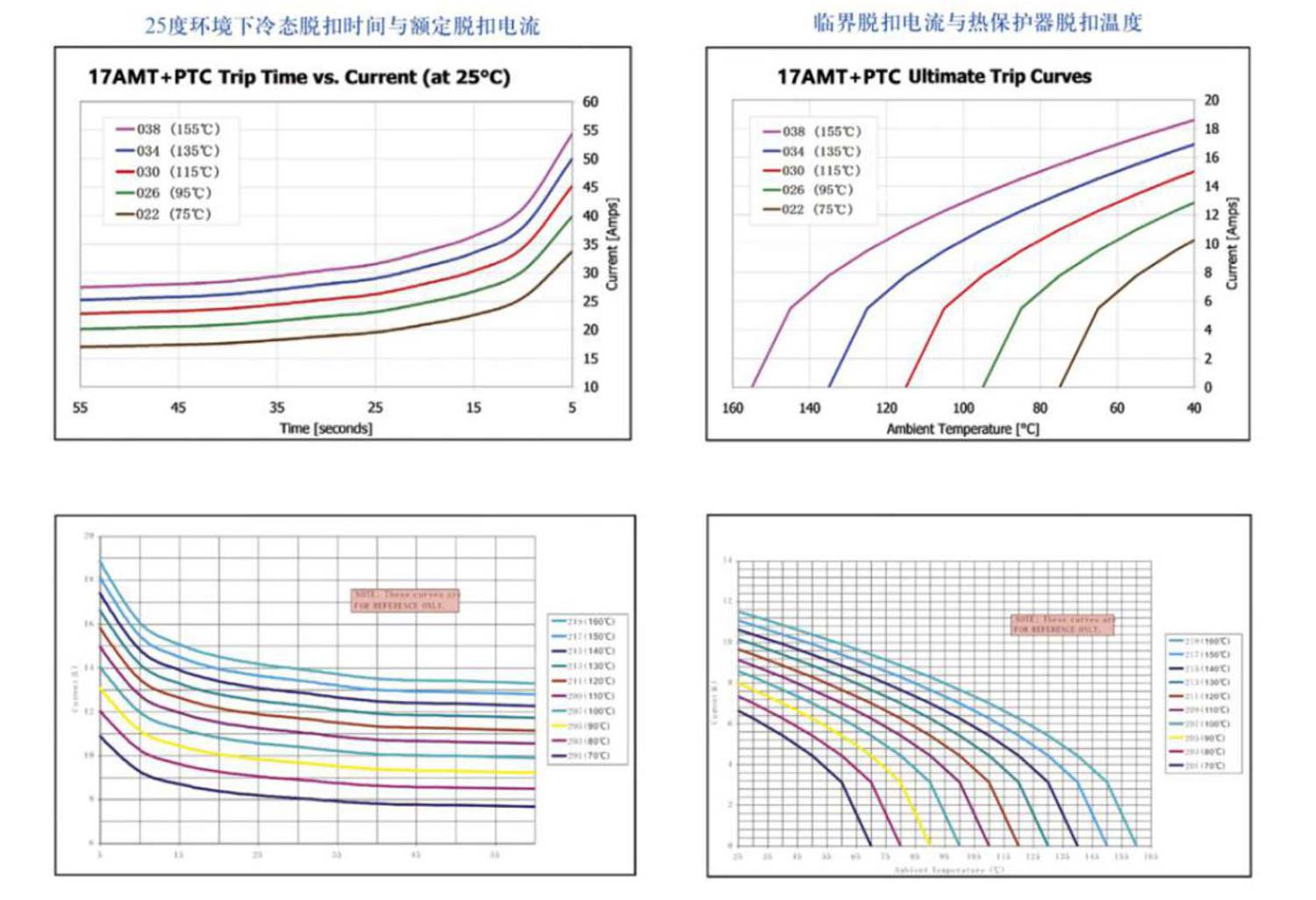

Characteristic Curve

Approximate value is only used to select samples for certification test

These curves are only used to provide guidance when choosing a protector for a specific application. Other factors should be considered when choosing a protector, such as the distance from the heat source and the installation method. The trip time depends on the terminal configuration and installation conditions.