Categories

Product Overview

17AMT is a patented product developed by Ainuo Technology. Based on the 17AM temperature protector, S-type or spiral-shaped resistance heating elements of different resistances are connected in series to form a series protection circuit with bimetal, which can meet the current 1A-30A. Fast over-current and over-temperature protection, it can accurately control the damage to the motor due to motor stalling or current overload, and disconnect the motor circuit in time.

Design Principle

Design principle of automatic reset type:

(1) Principle of current overload protection: The heating element inside the 17AMT is matched with the bimetal. It can not only provide the normal operation of the equipment, but also has the function of accurately controlling the overheating and overcurrent tripping time. When the motor and transformer are in excessive current or the locked-rotor current exceeds the trip value set by the thermal protector, the protector can instantly cut off the circuit to protect the electrical appliance. Design range of current overload trip value: 1A~30A.

(2) The principle of temperature overload protection: The bimetallic plate inside the 17AMT can accurately sense the working temperature of the electrical appliance. When the abnormal normal operation of the electrical appliance such as malfunction, overload, and stall causes the surrounding temperature to be too high, the bimetallic plate of the 17AMT reacts quickly Causes the silver contact to break, so that the electrical disconnection is protected. When the 17AMT cools to a safe temperature, the contact automatically closes and resets.

Applied Range

It is widely used in series motors, grinders, mixers, electric tools, garden tools, vacuum cleaners, ballasts, water pumps, various equipment with rotating parts, and electrical appliances.

Contact capacity: | 125V AC 50A for TCO |

250V AC 30A for TCO | |

Temperature range: | 40℃ to 180℃ for TCO |

Disconnect temperature tolerance: | ±3℃, ±5℃, ±7℃, ±10℃, can be customized according to customer needs |

Automatic action: | Motor is 3C type |

The ballast is 2C type | |

TCO is 2B type | |

Working hours: | continuous work |

Pollution status: | conventional |

Sensing element range: | full control |

PTI value of insulating material: | 250 |

Protection level: | IP00 |

Electrical connection: | on the winding, plug-in type, clamping type, bracket type, glue type, etc. |

Safety Certification

UL&CUL: E258861 (UL2111 standard); E347255 (UL873&UL60730-1&UL60730-2-9 standard)

CQC: 10002045187 (GB14536.1-2008; GB14536.3-2008) motor thermal protector

10002045187 (GB14536.10-2008) multi-purpose temperature sensitive controller

10002048854 (GB14536.1-2008; GB14536.4-2008) ballast thermal protector

TUV: 50178359 (EN60730-1 standard, EN60730-2-9 standard)

VDE: 40030705 (EN60730-1 standard; EN60730-2-2 standard)

CB: CN33917 (IEC60730-1 standard; IEC60730-2-2 standard)

Patent number: ZL201420780076.6; ZL201420780042.7

Temperature Specification

Action temperature: 40~180℃±5℃, every 5℃, it is a temperature specification.Reset temperature: 2/3 of the nominal operating temperature, with a tolerance of ±15°C, or can be customized according to customer requirements.

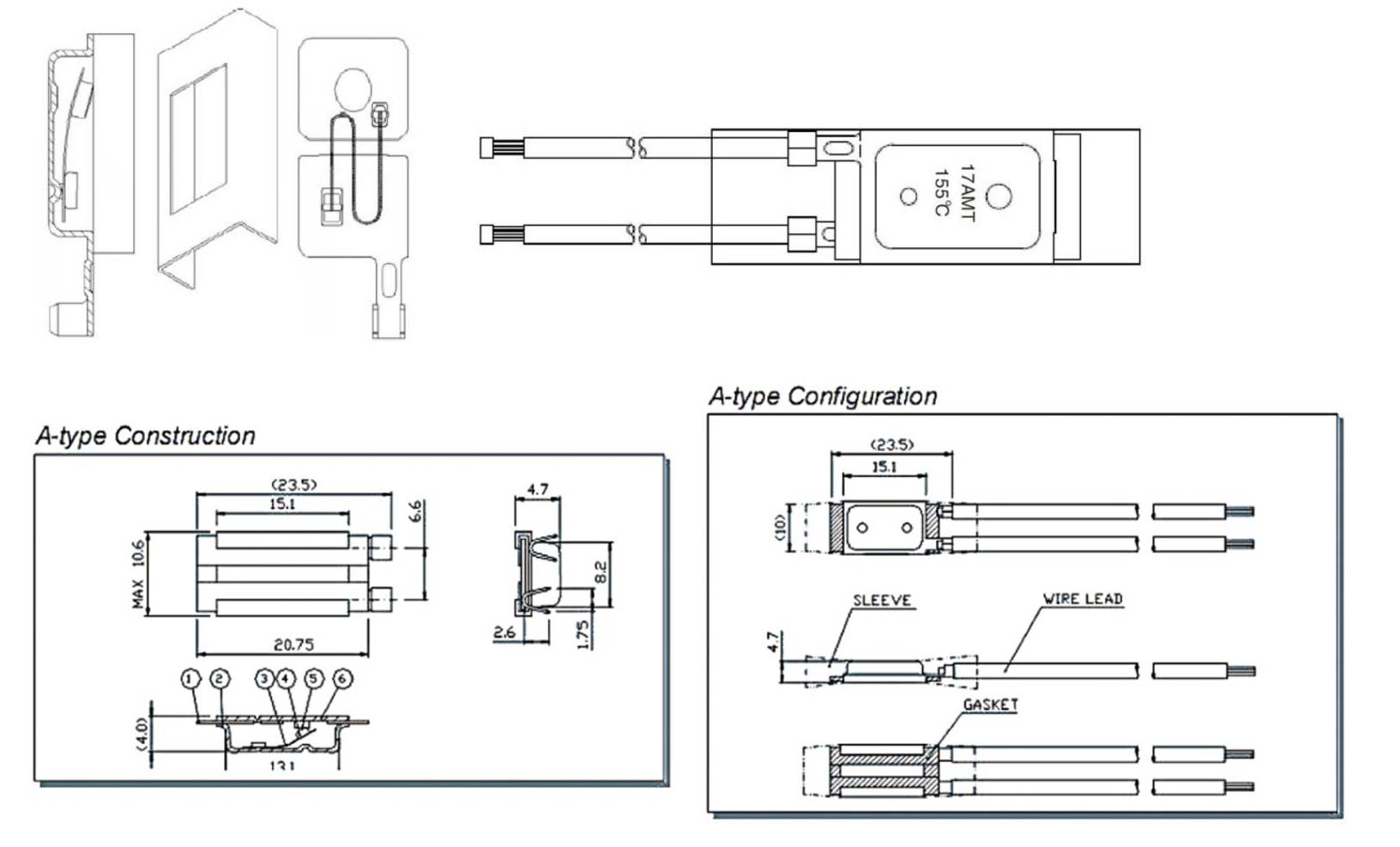

External Structure

Number Naming Reference

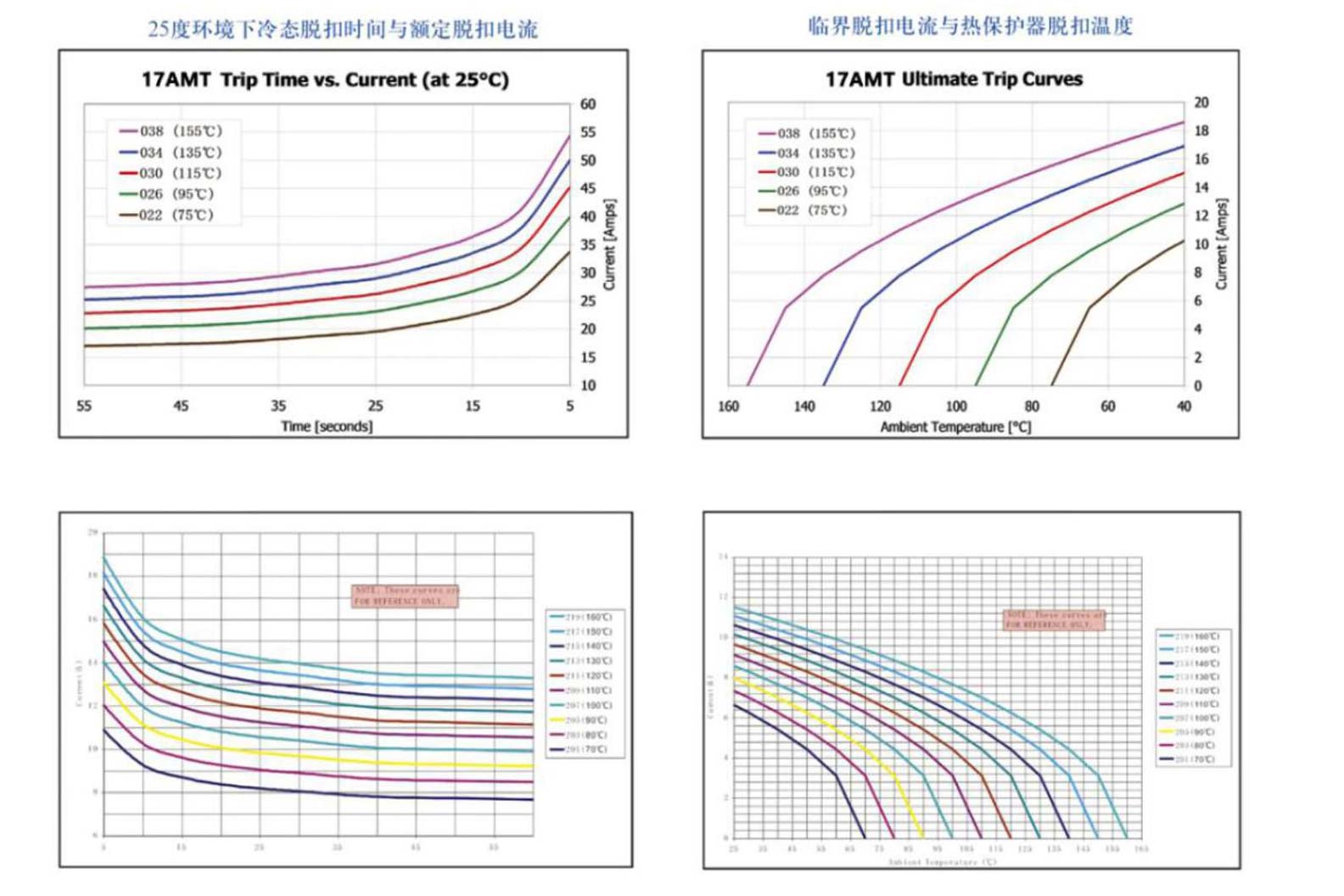

Characteristic Curve

Approximate value is only used to select samples for certification test

These curves are only used to provide guidance when choosing a protector for a specific application. Other factors should be considered when choosing a protector, such as the distance from the heat source and the installation method. The trip time depends on the terminal configuration and installation conditions.