Thermal motor protection installation considerations

Sep 13, 2022|

Sep 13, 2022| View:443

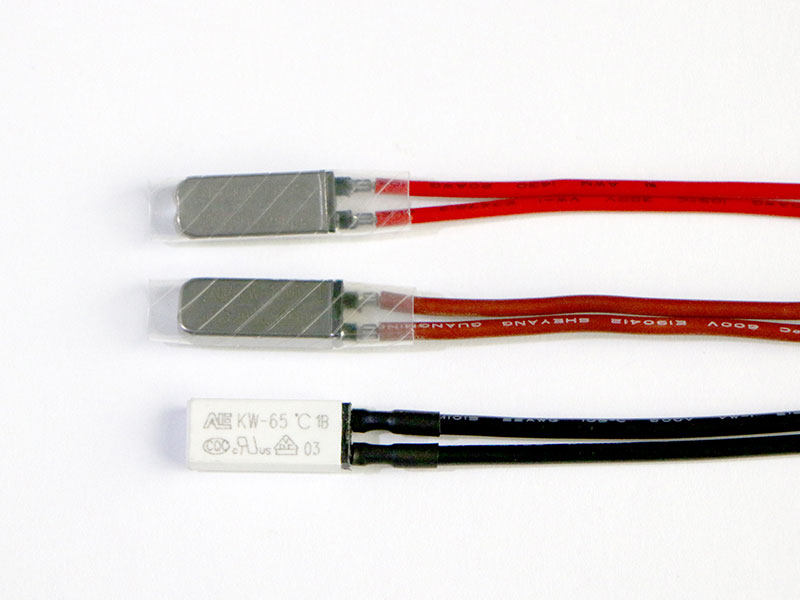

View:443Thermal motor protectionis a thermostat consisting of two different alloys that automatically close/disconnect the contacts when the temperature drops to a set temperature, returning them to normal working conditions. Thermal motor protection is widely used in household electrical motors and electrical equipment, such as washing machine motors, air-conditioning fan motors, transformers, ballasts, and electric heating appliances. When installing thermal motor protection, the following should be noted:

1. When the lead is bent, it should be bent from the part more than 6mm away from the root. When bending, the root and the lead must not be damaged, and the lead must not be pulled, pressed, or twisted by force.

2. Thermal motor protection the use of screws, rivets, or studs, should be able to prevent the occurrence of mechanical creep and poor contact phenomenon.

3. The connecting parts shall be able to work reliably within the working range of the electrical appliance without displacement due to vibration or shock.

4. When welding the lead, the heating humidity should be limited to the minimum, and the thermal motor protection should not be added to the high temperature; no force pulling, pressing, twisting, and twisting of the hot fuse and lead; after welding, should be cooled immediately for more than 30 seconds.

5. Thermal motor protection shall only be used at specified rated voltages, currents, and specified temperatures, paying particular attention to the continuous temperature tolerance of the thermal motor protection.