Application of industrial thermostat controller in solid thermostat heating

Aug 30, 2022|

Aug 30, 2022| View:432

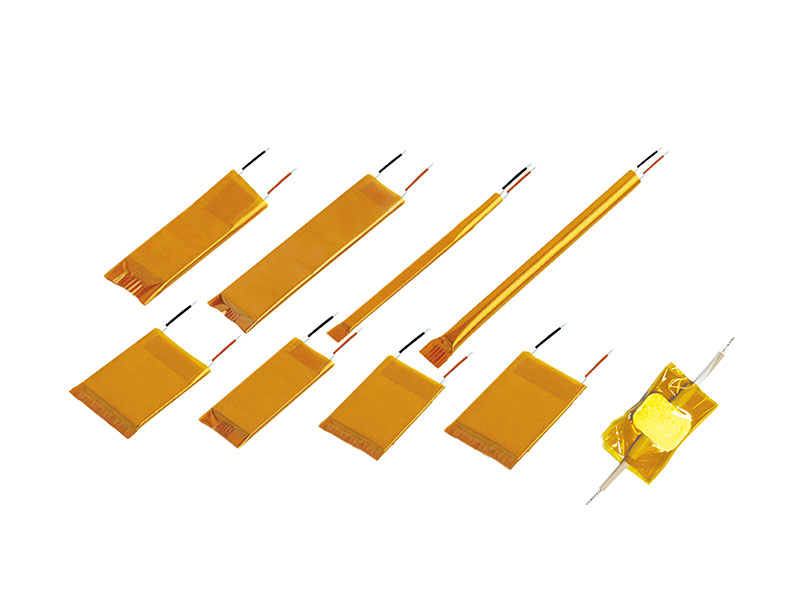

View:432Industrial Thermostat Controllerhas the advantages of low thermal resistance and high heat transfer efficiency. The utility model is an automatic constant temperature energy-saving electric heater. The principle of constant-temperature heating PTC thermistor is: the self-heating of the PTC thermistor after heating makes the resistance value enter the jump zone, and the surface temperature of the PTC thermistor keeps constant during constant-temperature heating, the temperature is only related to the Curie temperature and applied voltage of the PTC thermistor, not the ambient temperature.

An industrial thermostat controller is a kind of heating device which adopts PTC thermistors of constant temperature heating. The industrial thermostat controller is adopted for solid constant temperature heating. The suitable heating temperature is 0 ~ 300 ° C, and the normal temperature is 50 ~ 300 ° C. The suitable ambient temperature is -40 ~ 250 °C. PTC with too high or too low surface temperature is difficult to manufacture, even without PTC characteristics. Working Voltage 3.7 V ~ 420V, AC and DC can be. When the operating voltage is low, PTC resistance at room temperature is very small, resistance temperature change rate is also very small, constant temperature accuracy is poor, or even can not rise to a higher temperature. The service life of a PTC constant temperature heater is several times that of a traditional electric heating wire heater. The use of PTC can also save service life costs and maintenance costs.

The industrial thermostat controller heats up quickly and is easy to design and can be used at any power with relatively little safety risk.